Technical features

Exclusive technology for any application

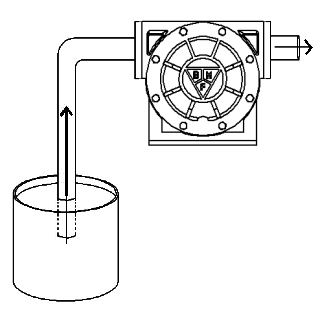

Self-priming

Automatically priming with vacuum creation in suction side.

Reversible

Fully reversible with same technical features in both directions of rotation.

Elastic

The elastic device of the oscillating hollow disc allows the passage of solid parts.

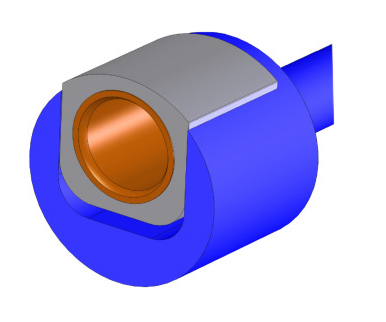

Leaks proof technology

The magnetic coupling completely seals the pump without using any mechanical seal.

Low rotation speed

The low operating speed does not emulsify the liquids and guarantees high reliability.

Atex zone 1 standards

Atex zone 1 compliance for all applications in explosion proof areas.

Working principle

Elastic, simple, robust

The oscillating hollow disk moves inside the body generating two volumes, the suction volume and the discharge volume, separated by the diaphragm. The fluid passes through the openings of the pump body. The hollow disk is kept pressed against the walls of the body by a spring which makes the system elastic and allows the passage of solid bodies. Compared to competitor models, the new range of hollow disk pumps developed by Belli Meccanica starting from 2008, has wider sliding surfaces and reduced eccentricity of the disk. These technical improvements ensure excellent performance and superior reliability.

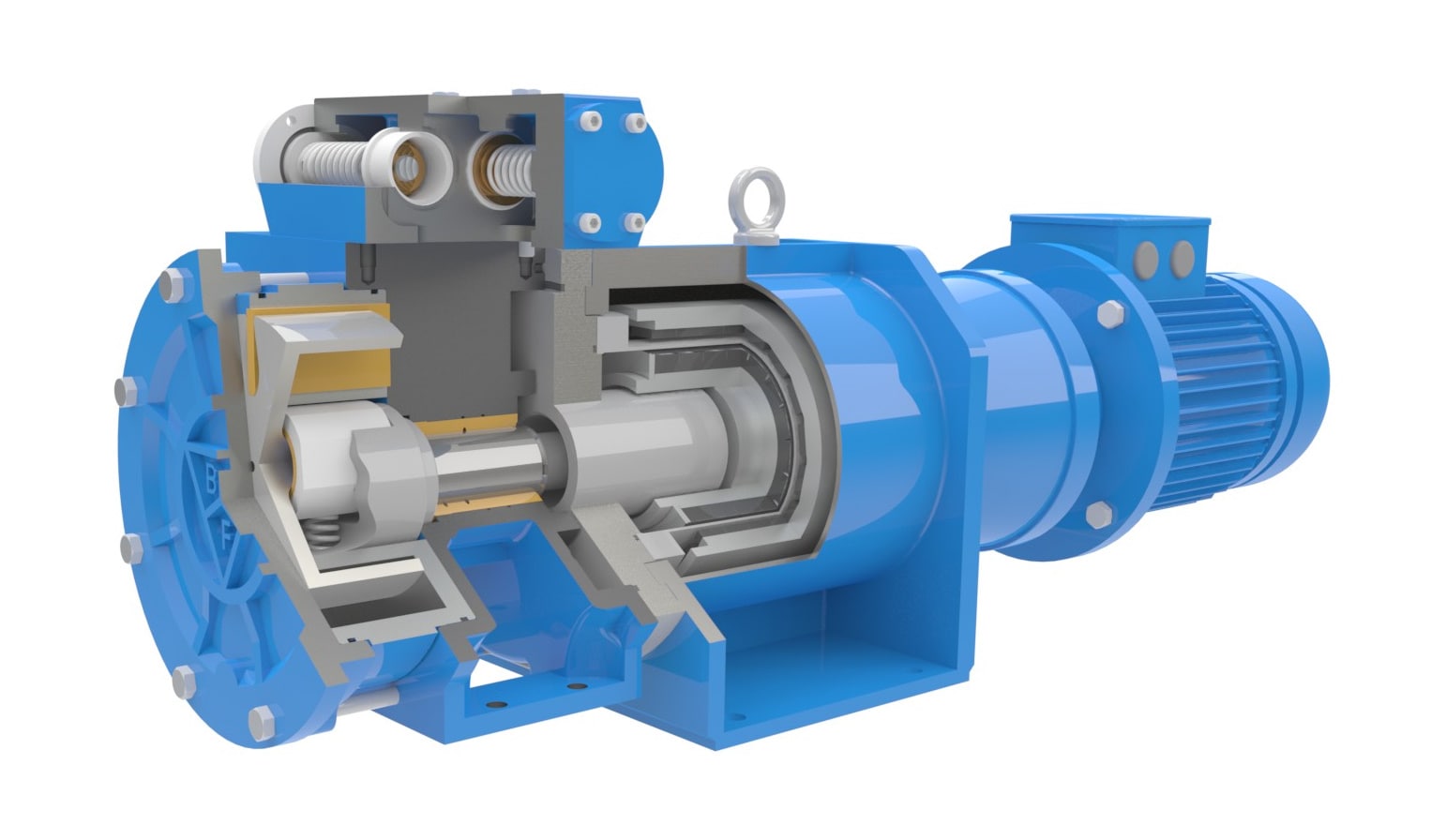

Technical features of the hollow disk MAG series pumps

The magnetic drive coupling transmits the motion to the pump shaft thanks to the use of powerful permanent magnets. Torque transmission occurs without any contact between mechanical parts and the containment canister totally seals the pump from the external environment avoiding any risk of leakage.