Our skids to offer a complete ready-to-use solution

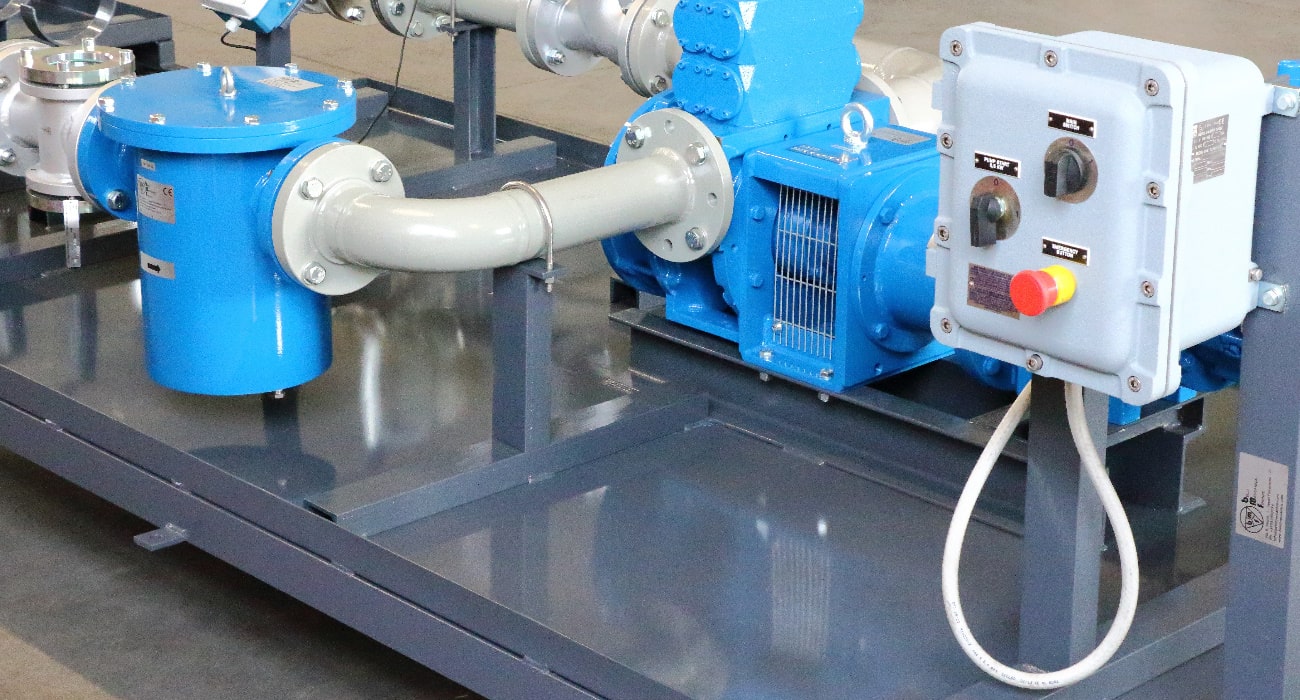

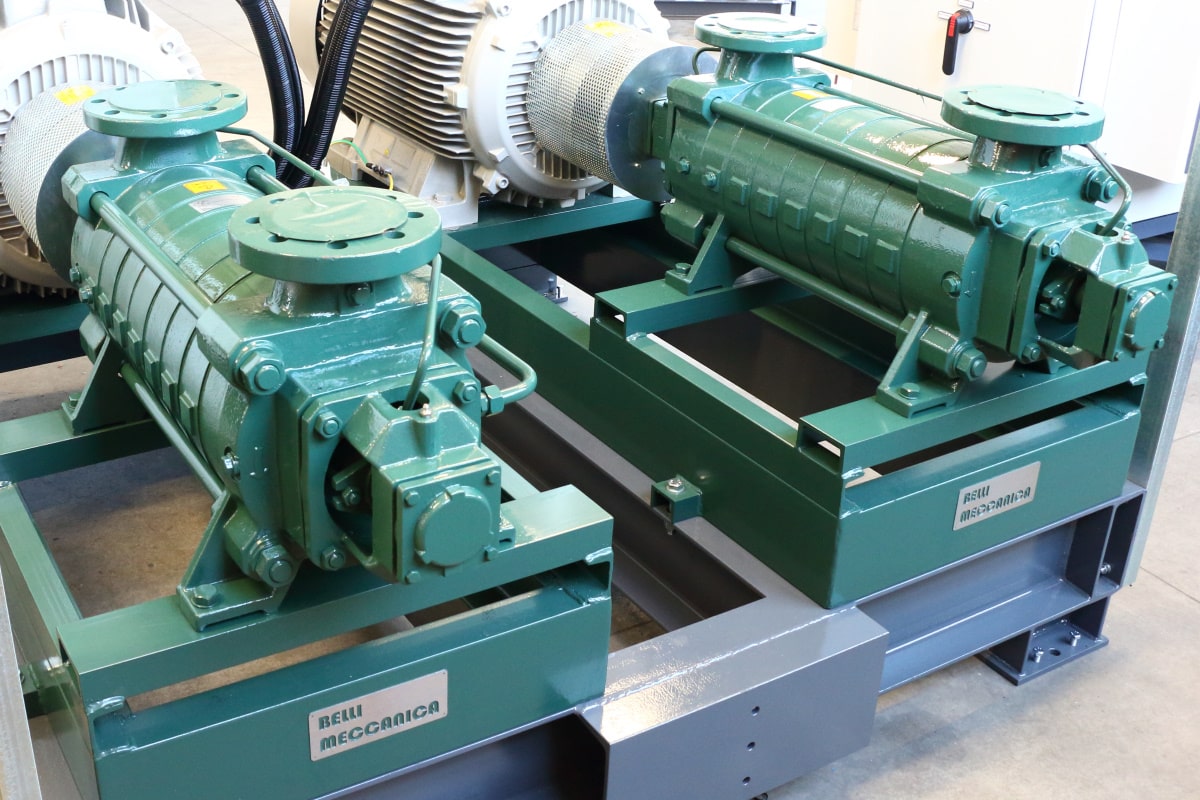

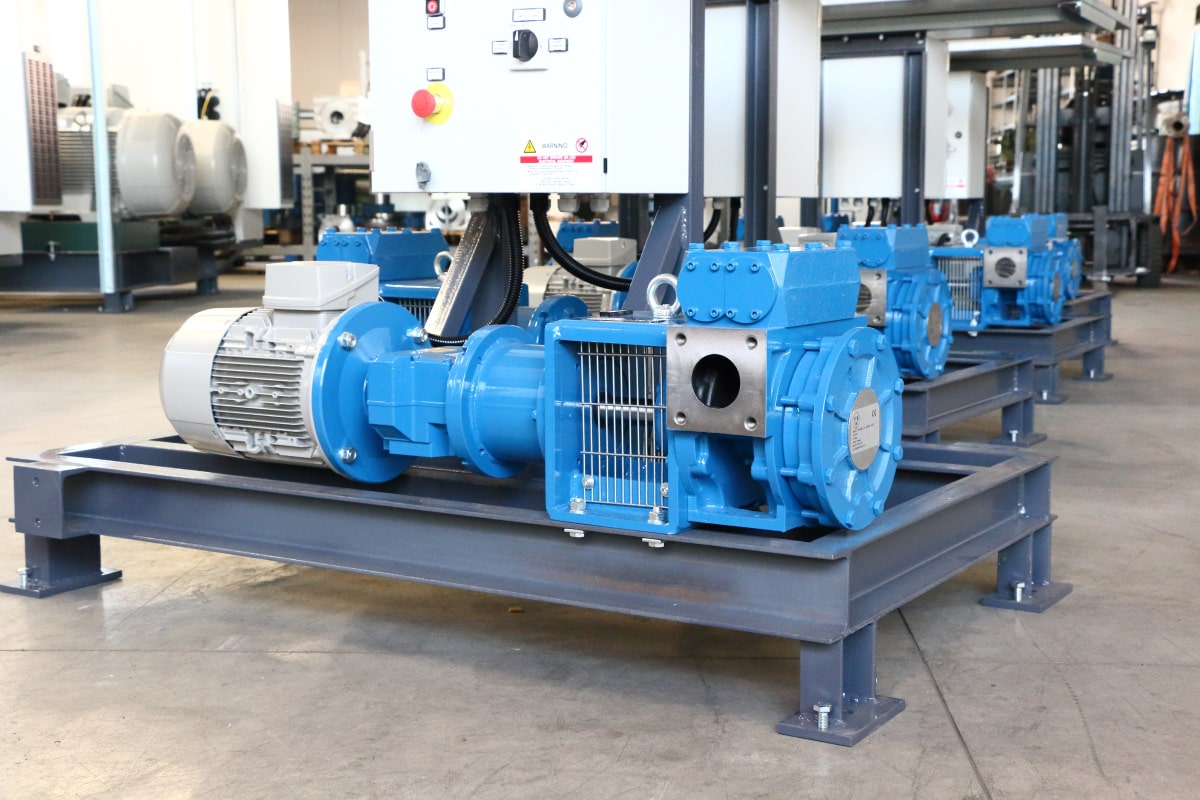

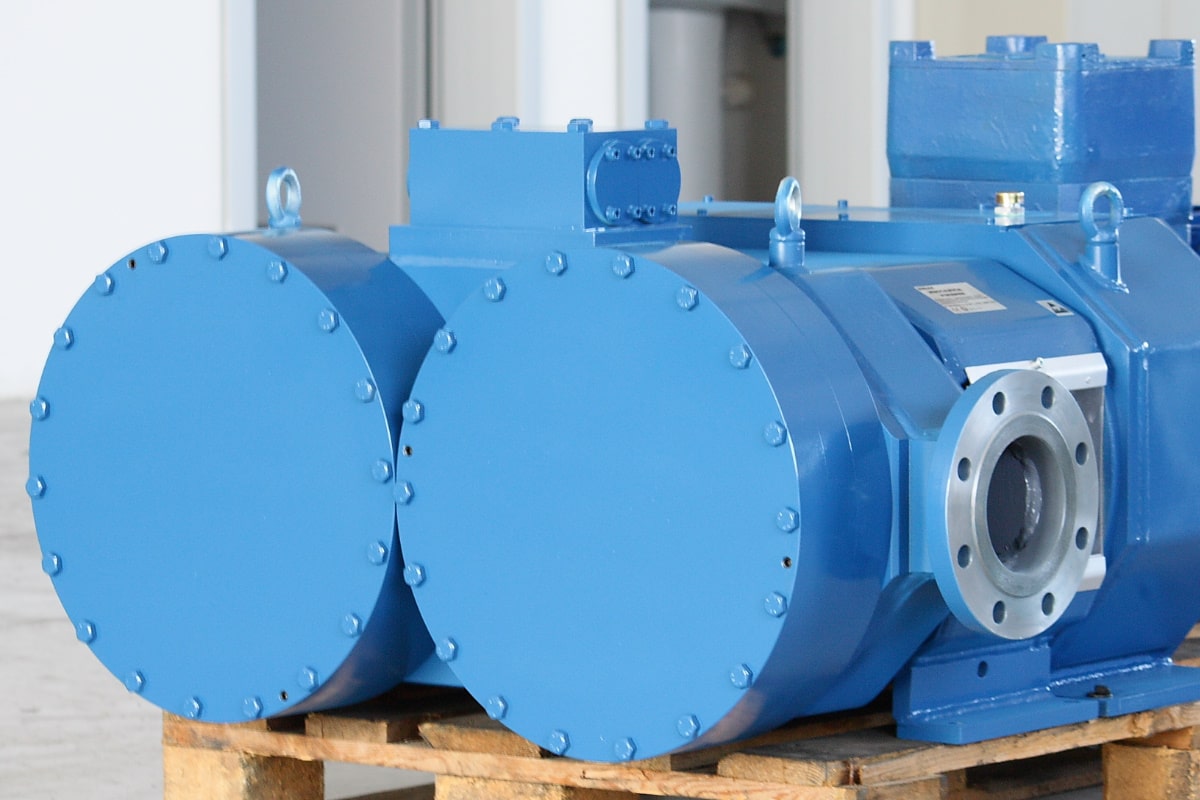

Our skids are designed and developed by our technicians according to customer needs to offer a complete tailor-made solution that guarantees ease of use and reliability in any application, even for ATEX 1 classified areas. The skid provides to the pump with all the components necessary to optimize its operation and to connect the pump to the rest of the plant through a complete ready-to-use package designed and optimized according to the process specifications.

It is usually composed of a baseplate equipped with a collection tank, electrical panel, flow meter, pressure gauge, pre-filter, valves, piping, wheels and anything else required by the customer specifications. We can also provide advanced 4.0 solutions with electrical panel complete with programmable PLC and instrumentation interconnected to the factory network through a special software and man-machine interface. In this case, the pump and electrical panel assembly are compliant to the requirements of industry 4.0.