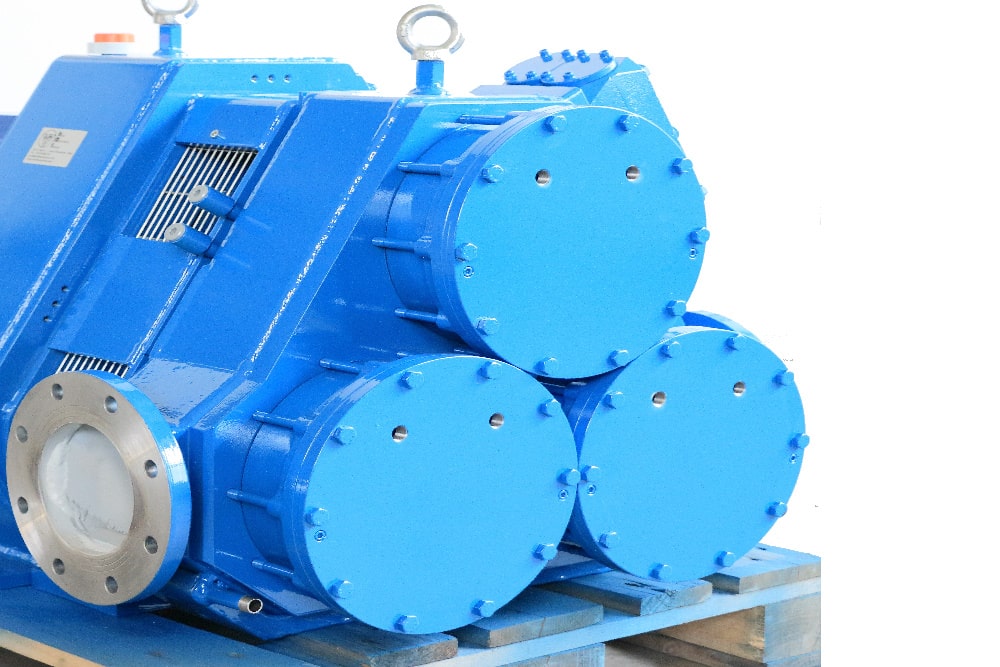

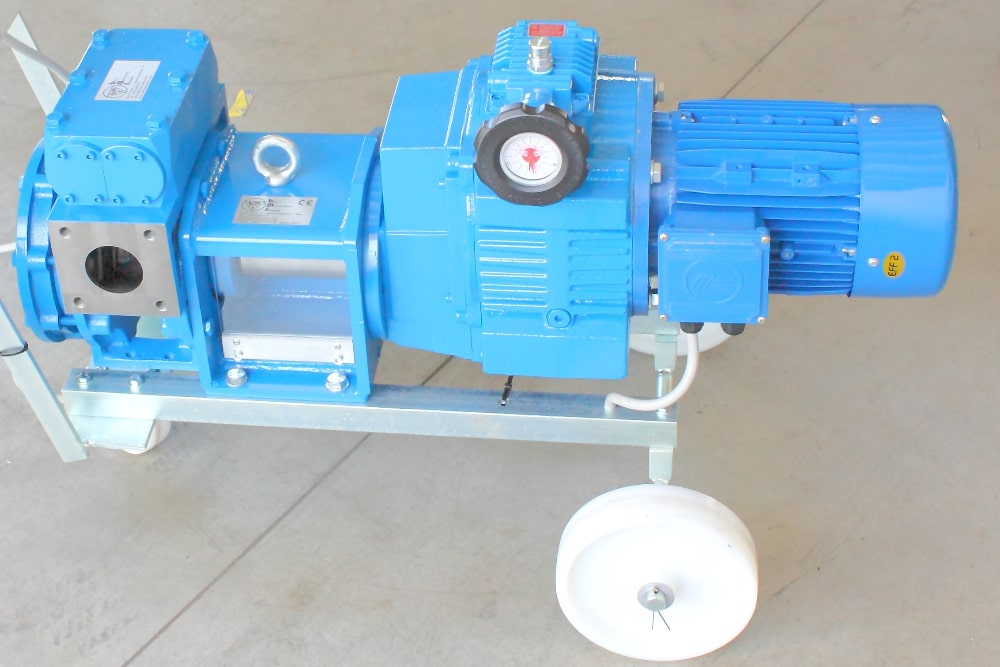

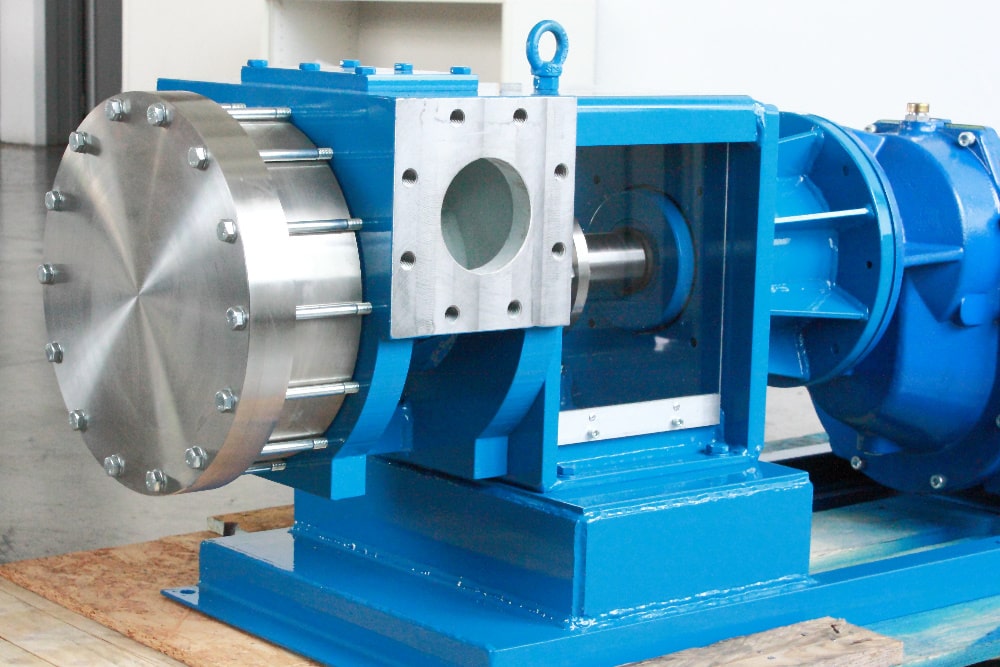

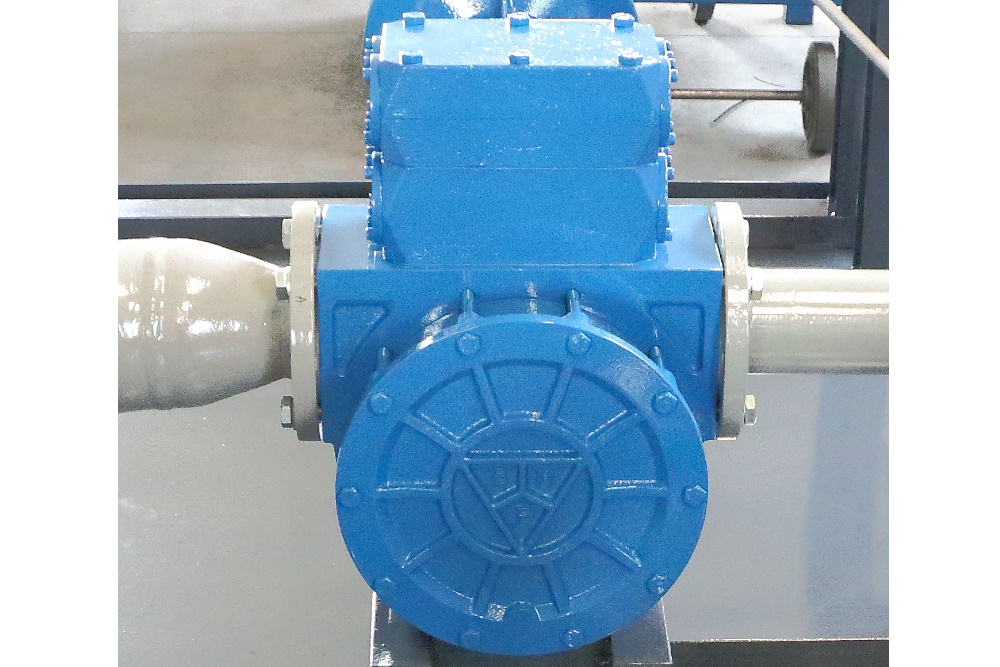

Volumetric pumps

Belli Meccanica is a leading company in the production of positive displacement and oscillating hollow disk pumps. In our workshops products of the highest quality are made thanks to the constant commitment to research and development of new production technologies. Thanks to our technical experience and patents, we offer innovative solutions with flow rates from 1 to 500 mc / h and pressure up to 15bar (g) for any type of application and field.