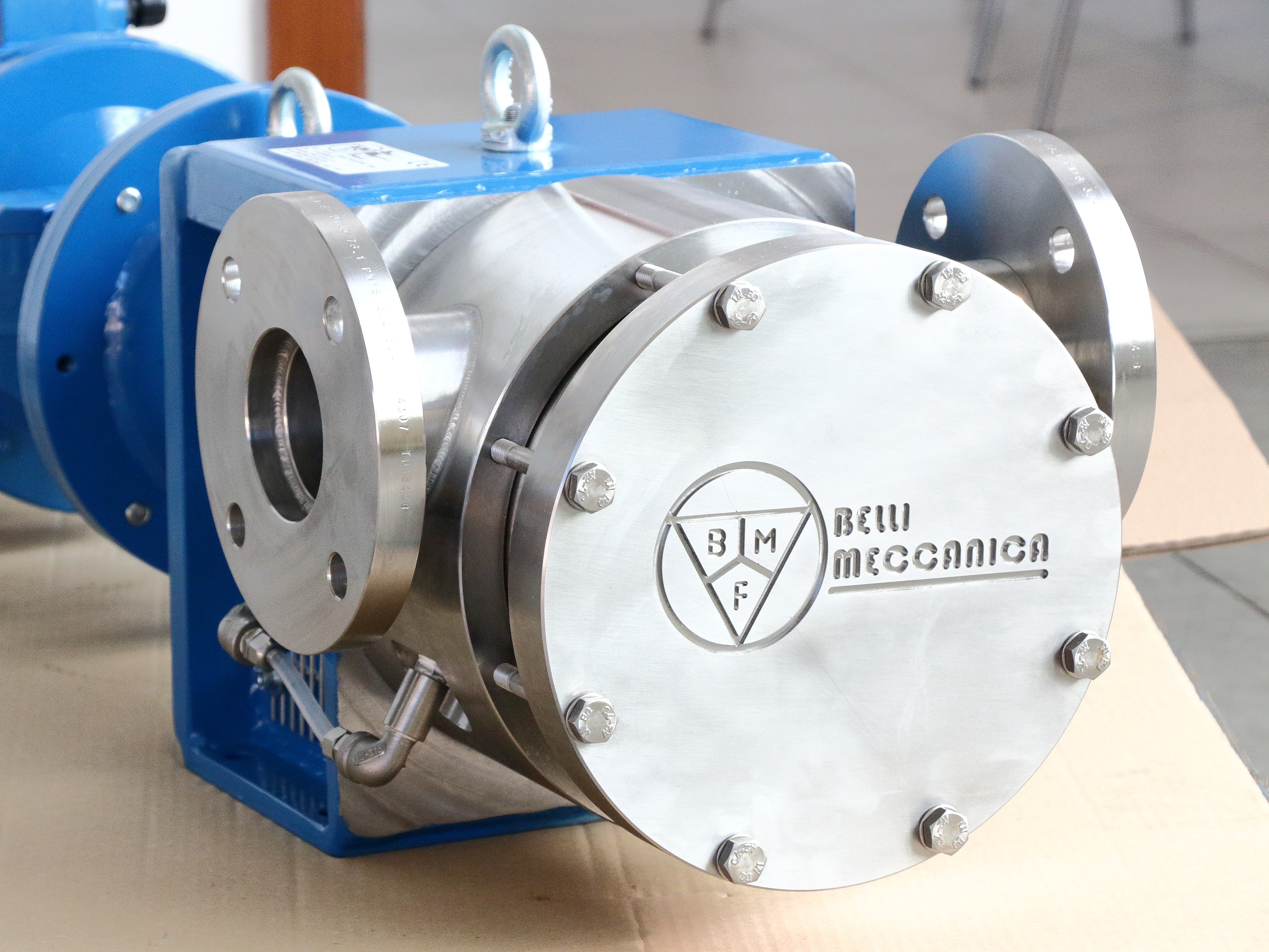

AP series positive displacement-almost-vacuum pumps

The AP series process pumps are part of the tailor made production of Belli Meccanica.

The body of these pumps is equipped with a particular structure with guide that allows to work up to 12bar of pressure in continuous service 24/7 and with impressive dry suction rate. The pump body is designed and customized according to the flow rate and operating pressure required, in order to produce a pump with specific sizing and perfectly calibrated on the application. The materials are selected according to the characteristics of the liquid to be pumped and go from cast iron and carbon steel to stainless steel or bronze. This type of pump is also manufactured according to Atex zone 1 standards, with single or double body and with flow rates up to 500mc / h and is used in all those processes where very high reliability is required in continuous service. For example fuel supply of burners or injection of additives or methyl esters in large pressure pipes are typical applications of these pumps.

The AP series pumps have an impressive dry suction lift capability: more than -0.9 bar of vacuum (more than 9 meters of water column). The internal special geometries and perfect clearances makes the pump capable of working also with mix of liquid and gas bubbles, pushing with a behaviour similar to a compressor.

The npsh required by the pump is very low up to 0,5m of npshr.

These particular features makes the pump a sort of hybrid self priming-vacuum-compressor pump that can work fine also with vessels and reactors in vacuum and in applications where the liquid is very close to the boiling point.